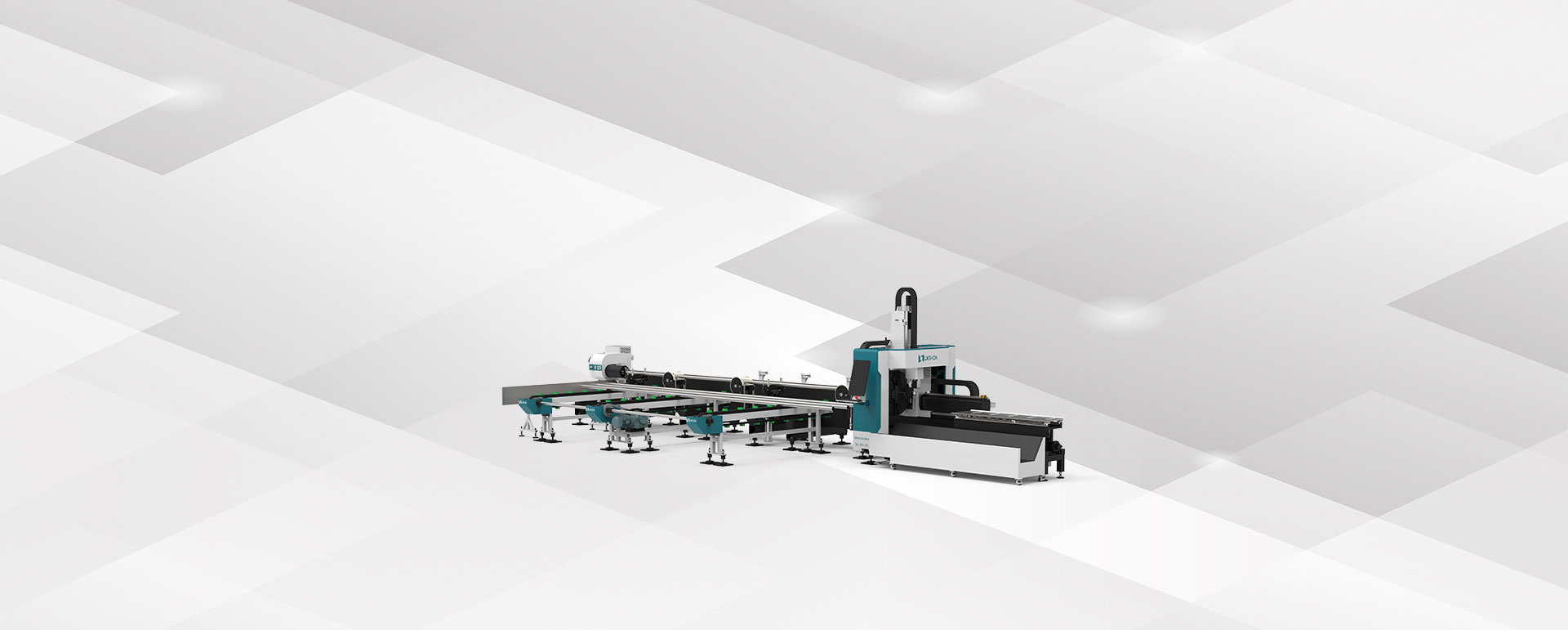

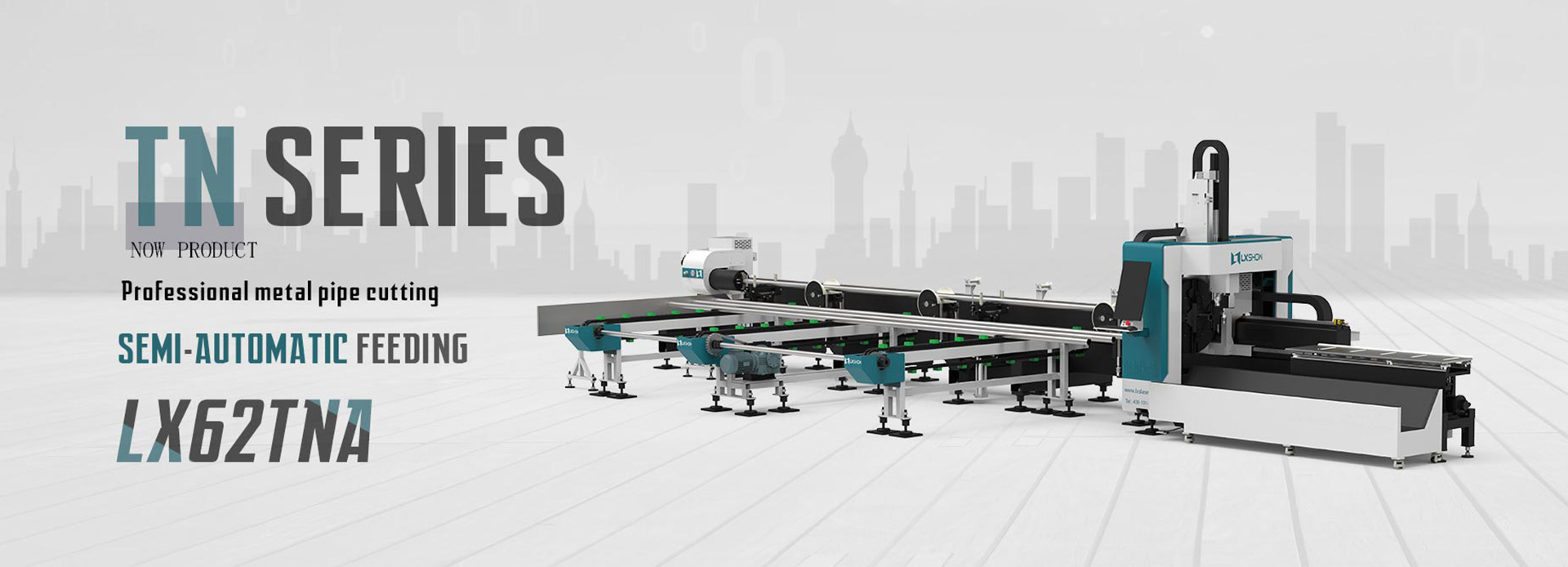

Tsarin Rataye-Gida Mai Wuya Ɗaya-Gado Mai Walda

Gadon yana ɗaukar tsarin rataye gefe da kuma gadon da aka haɗa da wani yanki ɗaya, wanda aka haɗa shi don kawar da damuwa ta ciki. Bayan yin aiki mai tsauri, ana yin tsufar girgiza kafin a gama yin injin, wanda hakan ke inganta tauri da kwanciyar hankali na kayan aikin injin da kuma tabbatar da daidaiton kayan aikin injin. Ana sarrafa na'urar AC servo ta hanyar tsarin sarrafa lambobi, kuma chuck yana gano motsi mai daidaitawa a cikin hanyar Y bayan tuƙin motar, yana fahimtar motsi mai sauri da motsi mai ciyarwa. An yi duka rack na axis na Y da layin jagora na layi da samfuran da suka dace, waɗanda ke tabbatar da daidaiton watsawa; ana sarrafa maɓallan iyaka a ƙarshen bugun biyu, kuma ana shigar da na'urar iyaka mai tauri a lokaci guda, wanda ke tabbatar da amincin motsi na kayan aikin injin yadda ya kamata; kayan aikin injin yana da kayan aikin shafawa. Na'urar shafawa ta atomatik tana ƙara mai mai shafawa ga sassan da ke motsawa na gadon a tazara ta yau da kullun don tabbatar da cewa sassan da ke motsawa suna aiki cikin kyakkyawan yanayi, wanda zai iya inganta rayuwar sabis na layukan jagora, gears da racks.

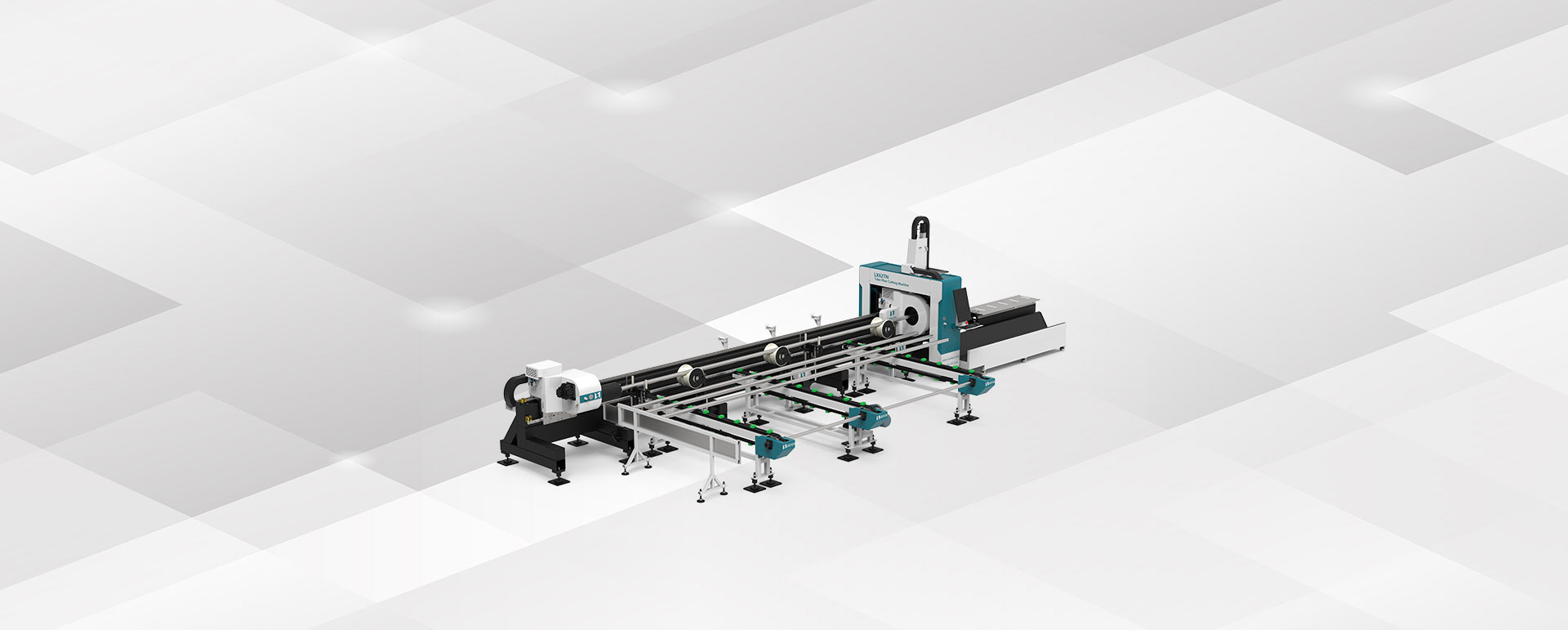

Na'urar Ciyarwa ta Gaba

Na'urar ciyarwa ta gaba ta haɗa da farantin tallafi wanda silinda mai iska ke sarrafawa, wanda ke tallafawa bututun lokacin da bututun da aka yanke ya yi tsayi kuma yana hana shi yin lanƙwasa.

Lokacin da ake yanke kayan aikin, silinda mai tallafi da aka ɗaga tana goyon bayan farantin tallafi don tallafawa bututun kuma tana hana shi yin lanƙwasa. Lokacin da aka yanke kayan aikin, silinda masu tallafi da aka ɗaga duk ana ja da baya, kuma kayan aikin suna faɗuwa zuwa farantin da ba ya buɗewa sannan su zame zuwa wurin ajiya. Tsarin yana sarrafa aikin silinda ta atomatik.

Sashen gaba kuma an raba shi zuwa nau'in bin diddigi da nau'in daidaitawa da hannu.

Tsarin Tallafi

Akwai nau'ikan kayan tallafi guda biyu da aka sanya a kan gadon, kuma akwai nau'i biyu da ake da su:

1. Ana sarrafa tallafin bin diddigin ta hanyar injin servo mai zaman kansa don motsawa sama da ƙasa, galibi don gudanar da tallafin bin diddigin don yawan lalacewar bututun da aka yanke (bututu masu ƙananan diamita). Lokacin da maƙallin baya ya matsa zuwa wurin da ya dace, ana iya saukar da tallafin don gujewa.

2. Silinda tana ɗagawa da sauke tallafin tayoyin da ke da diamita mai canzawa, kuma ana iya daidaita shi da hannu zuwa matsayi daban-daban na sikelin don tallafawa bututu masu girma dabam-dabam.

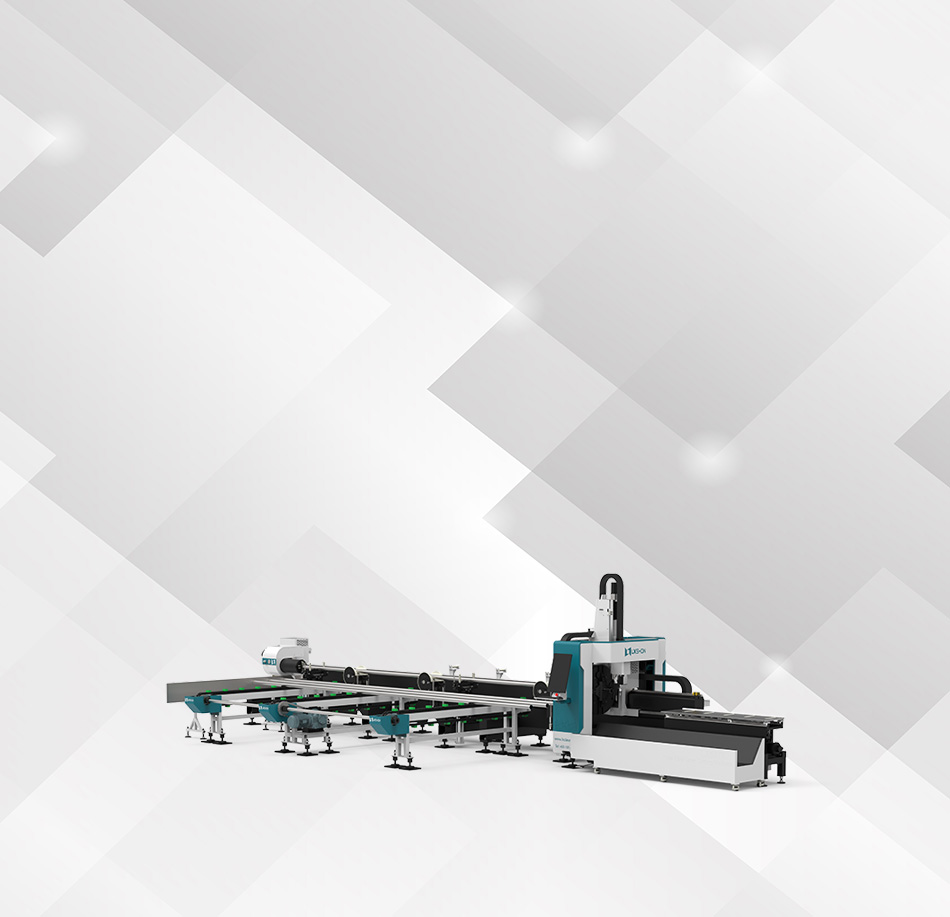

Chuck-Sashe

An raba bututun zuwa gaba da baya guda biyu masu cike da iska, waɗanda dukkansu za su iya motsawa a alkiblar Y. Akwatin baya yana da alhakin mannewa da ciyar da bututun, kuma ana sanya bututun gaba a ƙarshen gadon don kayan mannewa. Injinan servo ne ke tuƙa bututun gaba da na baya don cimma juyawa mai daidaitawa.

A ƙarƙashin haɗin gwiwa na matsewa biyu, ana iya yanke gajeriyar wutsiya, kuma gajeriyar wutsiya ta baki na iya kaiwa 20-40mm, yayin da take tallafawa gajeriyar yanke dogon wutsiya.

Injin yanke bututun TN yana amfani da hanyar motsa chuck da gujewa chuck, wanda zai iya yin yankewa da chuck biyu a kowane lokaci, kuma ba zai sa bututun ya yi tsayi da rashin kwanciyar hankali ba, kuma daidaiton bai isa ba.

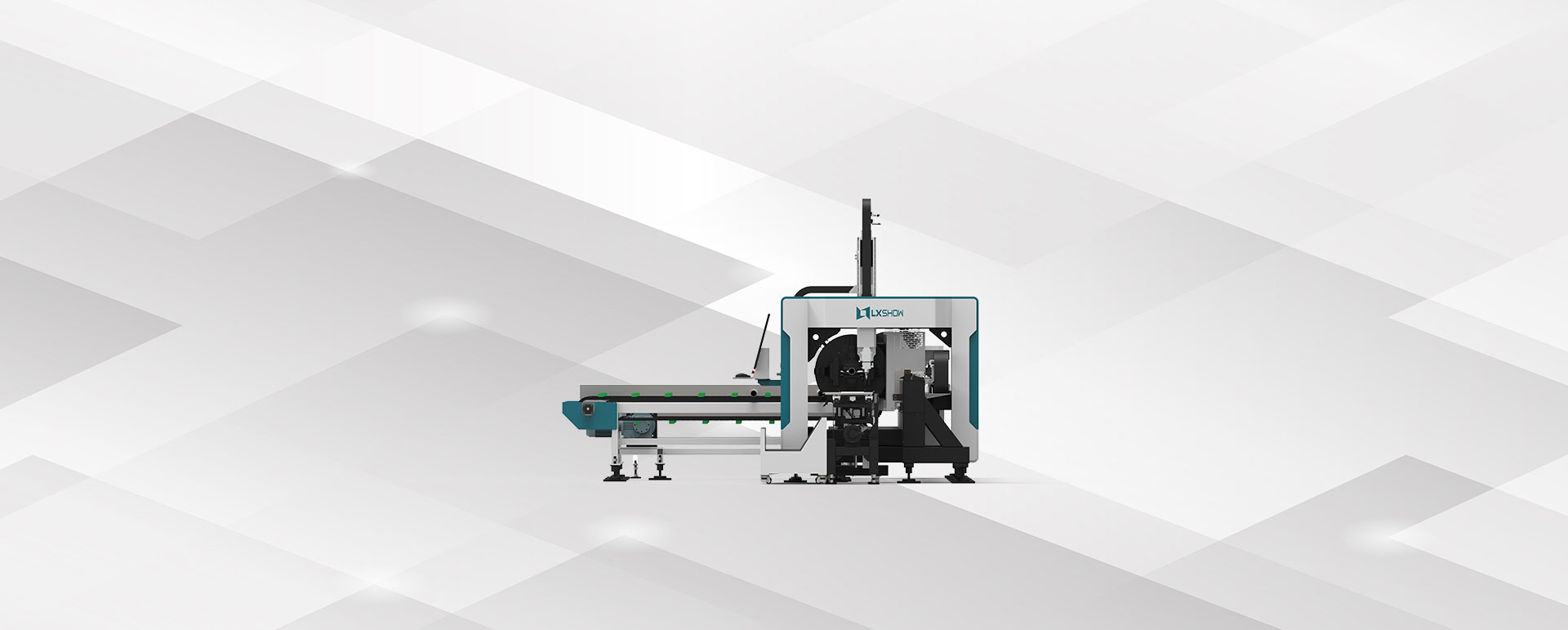

Na'urar Axis

Gilashin na'urar X-axis yana ɗaukar tsarin gantry, wanda aka haɗa shi da haɗin bututun murabba'i da farantin ƙarfe. An sanya ɓangaren gantry a kan gado, kuma injin servo ne ke tuƙa X-axis don tuƙa rack da pinion don cimma motsi mai daidaitawa na farantin zamiya a alkiblar X. A cikin tsarin motsi, maɓallin iyaka yana sarrafa bugun don iyakance matsayin don tabbatar da amincin aikin tsarin.

A lokaci guda, ma'aunin X/Z yana da nasa murfin gabobi don kare tsarin ciki da kuma cimma ingantaccen kariya da kuma kawar da ƙura.

Na'urar Z-axis galibi tana gano motsi sama da ƙasa na kan laser.

Ana iya amfani da axis ɗin Z a matsayin axis na CNC don yin motsin haɗin gwiwa, kuma a lokaci guda, ana iya haɗa shi da axis ɗin X da Y, kuma ana iya canza shi zuwa ikon bin diddigin abubuwa don biyan buƙatun yanayi daban-daban.

Na'urar Axis

Gilashin na'urar X-axis yana ɗaukar tsarin gantry, wanda aka haɗa shi da haɗin bututun murabba'i da farantin ƙarfe. An sanya ɓangaren gantry a kan gado, kuma injin servo ne ke tuƙa X-axis don tuƙa rack da pinion don cimma motsi mai daidaitawa na farantin zamiya a alkiblar X. A cikin tsarin motsi, maɓallin iyaka yana sarrafa bugun don iyakance matsayin don tabbatar da amincin aikin tsarin.

A lokaci guda, ma'aunin X/Z yana da nasa murfin gabobi don kare tsarin ciki da kuma cimma ingantaccen kariya da kuma kawar da ƙura.

Na'urar Z-axis galibi tana gano motsi sama da ƙasa na kan laser.

Ana iya amfani da axis ɗin Z a matsayin axis na CNC don yin motsin haɗin gwiwa, kuma a lokaci guda, ana iya haɗa shi da axis ɗin X da Y, kuma ana iya canza shi zuwa ikon bin diddigin abubuwa don biyan buƙatun yanayi daban-daban.

Injin Lantarki na Lantarki na Fiber Laser don Amfani da Bakin Karfe na Carbon

Kayan Aikace-aikace:

Injin Yanke Karfe na Fiber Laser ya dace da yanke ƙarfe kamar Tube Bakin Karfe, Tube Mai Sauƙi na Karfe, Tube na Karfe na Carbon, Tube na Karfe na Alloy, Tube na Karfe na Spring, Bututun ƙarfe, Bututun Karfe na Galvanized, Bututun Aluminum, Bututun Tagulla, Bututun Tagulla, Bututun Tagulla, Bututun Tagulla, Bututun Titanium, Bututun Karfe, Bututun Karfe, da sauransu.

Masana'antu na Aikace-aikace:

Ana amfani da Injinan Yanke Fiber Laser sosai wajen kera Allon Talla, Talla, Alamu, Alamomi, Haruffan Karfe, Haruffan LED, Kayan Kitchen, Haruffan Talla, Sarrafa Karfe na Tube, Kayan Karfe da Sassa, Kayan Ƙarfe, Chassis, Racks & Cabinets Sarrafa, Sana'o'in ƙarfe, kayan fasaha na ƙarfe, yanke panel na lif, kayan aiki, sassan mota, Tsarin Gilashi, Sassan Lantarki, Faranti na Suna, da sauransu.